Métautek’s Integration Success

Discover the full story of operational optimization through tailored ERP enhancement

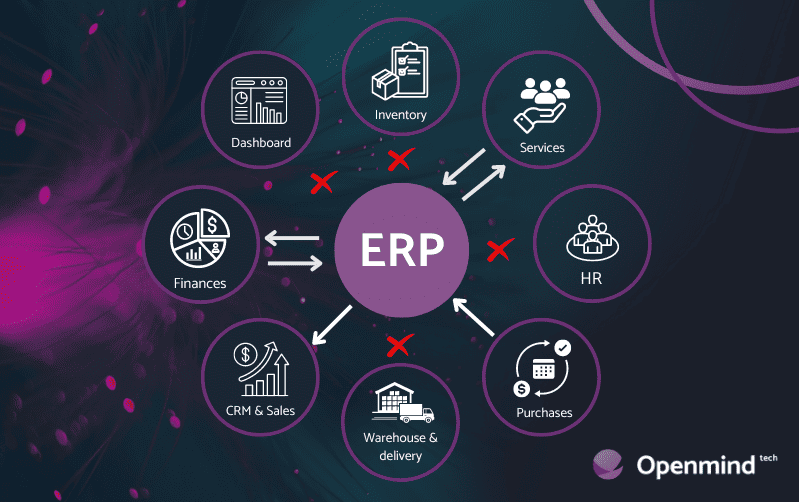

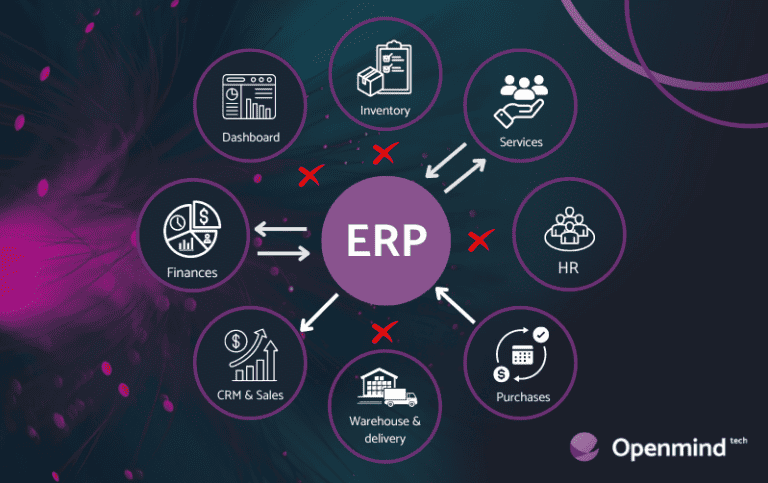

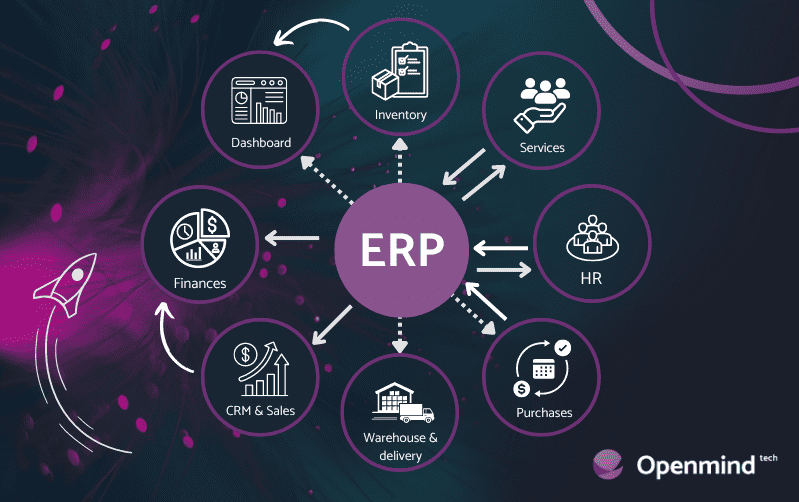

ERP systems are the lifeblood of many organizations, integrating various departments and functions to streamline operations and drive efficiency.

But simply having an ERP system in place isn’t enough to unlock its potential—regular optimization is crucial to ensure the system continues to serve your evolving business needs.

ERP optimization involves fine-tuning your system to align with your company’s processes and goals. This means customizing features, improving performance, integrating new modules, and addressing inefficiencies, all while maximizing the value of your existing ERP investment. The goal is to keep your system agile, efficient, and capable of supporting long-term growth.

By optimizing your ERP, you can tailor it to specific needs like:

A non-optimized ERP system leads to inefficient processes, fragmented activities and obstacles to the integrated management of company operations.

Manufacturing and distribution companies face several significant challenges when it comes to managing ERP systems. These challenges can impede the effectiveness and efficiency of their operations.

1. Dependence on a single technical resource: The common practice to overcome the limits of customizability and adaptability of the existing ERP system is to rely on a single technical expert. Companies will tend to create this gap through simple parallel systems, often using Excel spreadsheets. However, the vulnerability arises from dependence on a single technical resource, leading to potential risks when an employee with essential knowledge leaves the company.

2. Lack of leadership in innovation education: Many companies feel that they lack the support necessary to innovate and enhance their ERP systems. ERP systems, over time, may become stagnant and no longer align with a company’s evolving needs and market dynamics.

3. Lack of leadership in innovation support: Companies often struggle to find a clear leader who can provide quality support for innovation. Openmind has positioned itself as a reliable leader in this field. We offer specialized support services with an agile, personalized approach. Our team work with existing IT infrastructure and ensures that ERP systems are optimized efficiently, enabling companies to concentrate on value-added activities and tasks.

4. Obsolescence of ERP systems: As time passes, ERP systems can become outdated and no longer meet a company’s evolving needs. Openmind addresses this challenge by offering ERP system modernization services. We assist companies in transitioning to modern ERP solutions that better align with their current requirements and future growth strategies.

5. Lack of intelligence behind ERP systems:

For an ERP system to be considered intelligent, it must be designed with the company’s specific business processes in mind. This differs from design based on visions “imposed” by so-called tablet software, thus emphasizing customization and precise alignment with the company’s internal needs and workflows.

In other words, it’s not your business processes that have to adapt to the software, but rather the opposite.

6. Overlaying information technology: In manufacturing companies, information technology often needs to be overlaid on top of existing business processes, which can lead to integration challenges.

Discover the full story of operational optimization through tailored ERP enhancement

The benefits of ERP optimization

Openmind Technologies can innovatively address the challenges of ERP systems for manufacturing and distribution companies, offering tailor-made solutions for proactive innovation, effective support, streamlined IT integration and customized alignment with unique business processes.

Our approach can ensure that ERP systems evolve dynamically, enhancing operational efficiency and adaptability.

Subscribe to receive our exclusive updates directly to your email.

Tell us more about your needs so that we can better route your project to our specific SWAT team.

1

During the brainstorming phase, we work with you to identify potential solutions to your business challenges to generate the technology response that aligns with your business objectives.

2

Through our requirements gathering process, we work closely with you to define and prioritize your needs, ensuring that our solutions are tailored to meet your specific requirements.

3

This phase marks the beginning of our partnership. We’ll finalize the project plan and establish clear communication channels to ensure a smooth and successful project execution.