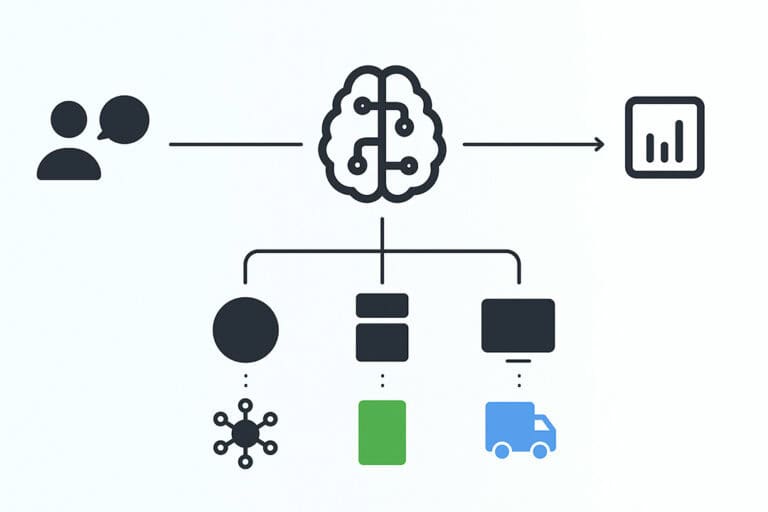

Mill Test Processing From Administrative Overhead to Intelligent Automation

Discover how digital automation and AI can streamline Mill Test (MTR) processing, reduce administrative burden, and improve reliability across the steel industry. Join this practical webinar.